Orders

Create and manage custom orders directly within Printago using your SKU library. Manual orders provide a streamlined way to track customer requests and queue multiple SKUs for production in an organized workflow.

Overview

Manual orders allow you to:

- Organize multiple SKUs into a single customer order

- Track order progress from creation to completion

- Configure OpenSCAD parameters for customized SKUs

- Automatically reconcile print jobs when order contents change

- Maintain order history and notes for customer reference

Creating Manual Orders

Starting a New Order

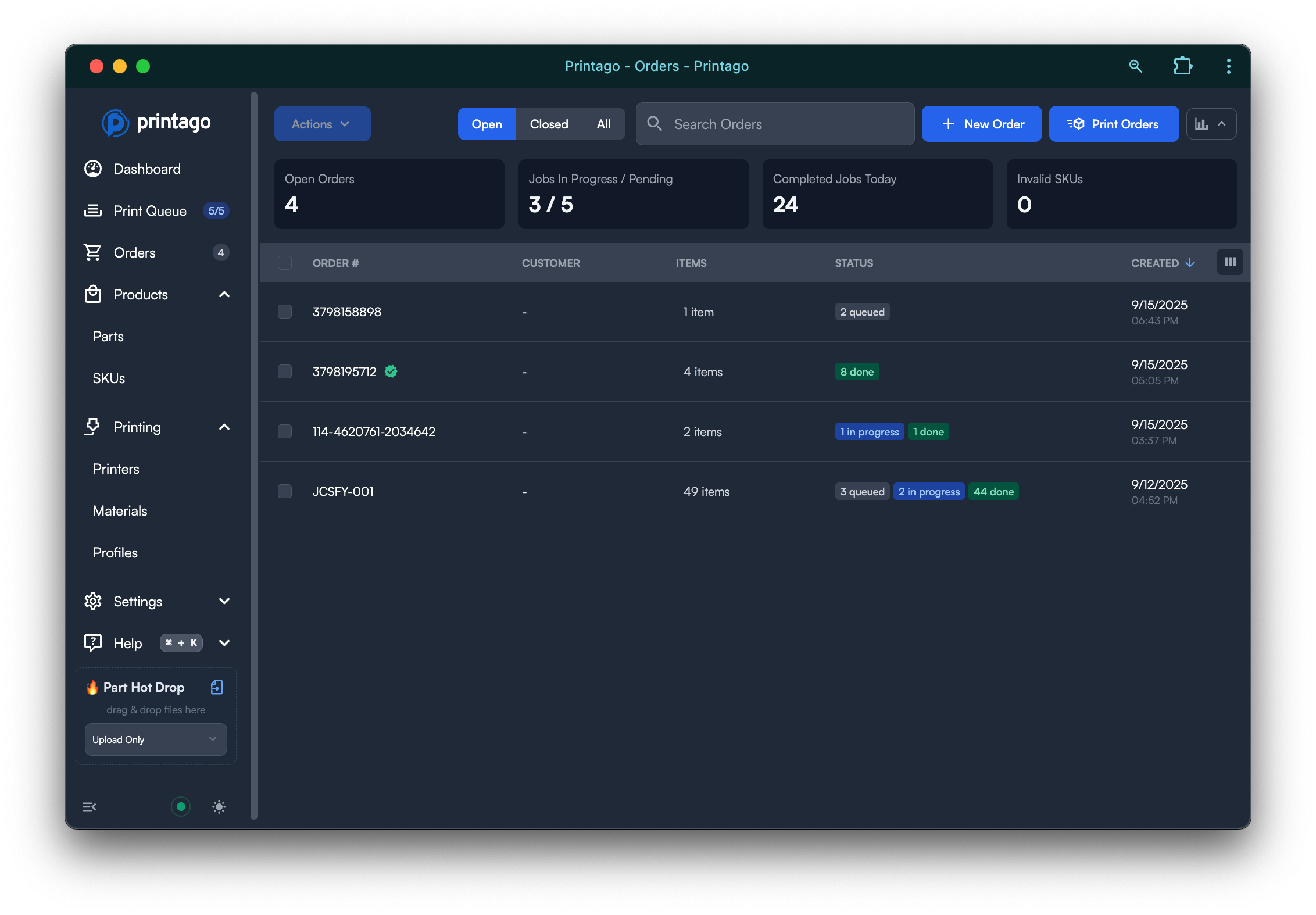

- Navigate to Orders from the Sidebar menu

- Click + Create Order

- Fill in the order details:

- Order Number: Custom identifier for tracking

- Customer Name (disabled currently): Optional for order identification

- Customer Email (disabled currently): Optional information for the order

- Fulfillment Date: Target completion date (optional)

- Notes: Any special instructions or details

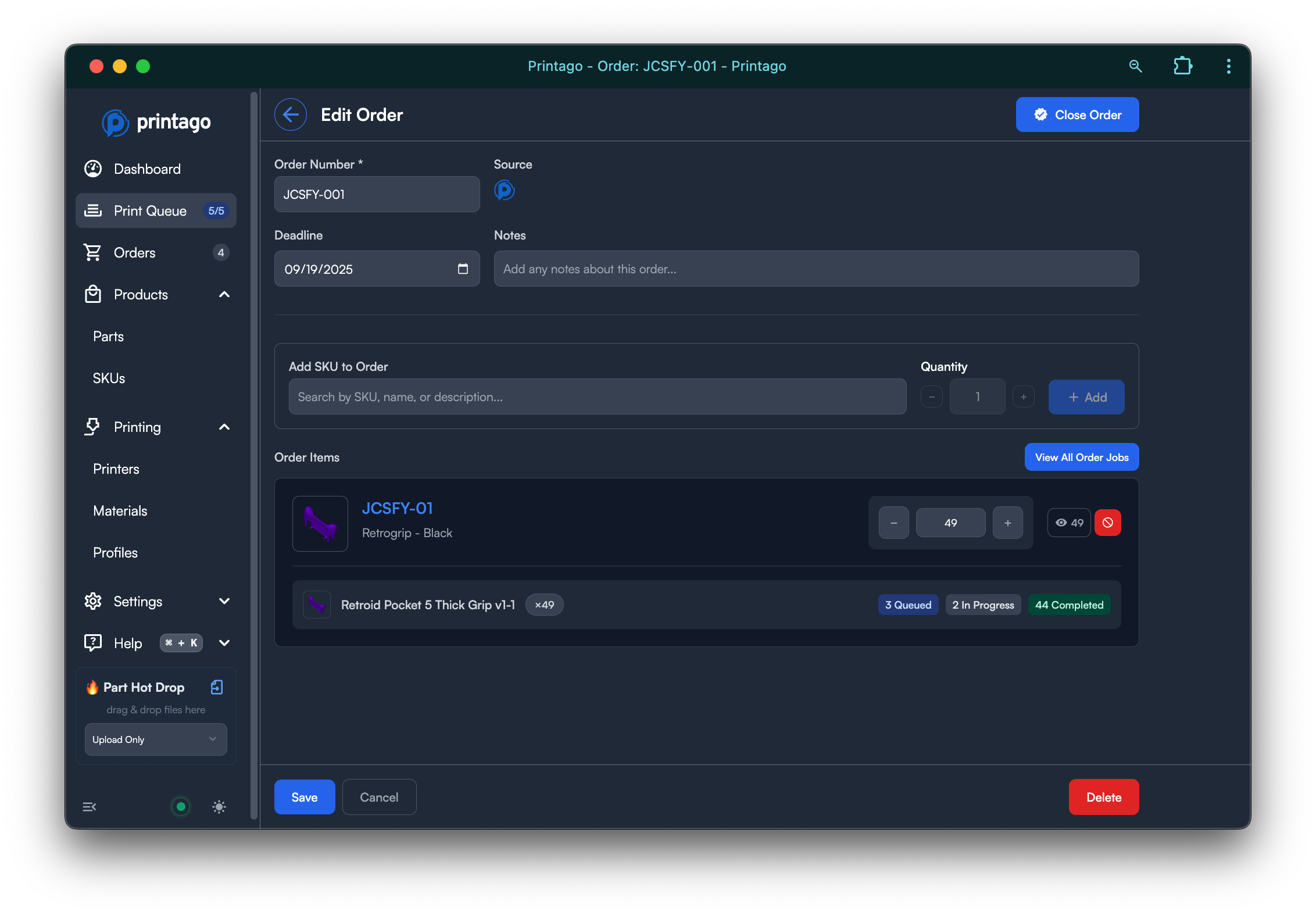

Adding SKUs to Orders

Add SKUs:

- Search and select SKUs from your product library

- Set quantities for each SKU line item

- Configure any customization parameters for OpenSCAD parts

- SKUs with exposed parameters will show configuration options

SKU Configuration:

- For OpenSCAD SKUs, customize any parameters marked as

SKU PARAM - Each SKU line item can have different parameter values

- Preview shows total parts that will be created across all SKUs

Save Order: Click save to create the order with all configured line items

Creating SKUs On-the-Fly

Missing SKUs: If you need a SKU that doesn't exist yet:

- Type the SKU name when adding line items

- Printago will prompt you to create the new SKU

- Configure the SKU with parts, quantities, and parameters

- The SKU is automatically added to your order after creation

Order to Print Queue Workflow

Understanding Print Job Creation

Each order tracks how many individual print jobs it will generate:

- Job Counter: Shows total print jobs from all SKUs in the order

- SKU Breakdown: Each SKU contributes based on its part count and quantities

- Dynamic Updates: Job count automatically adjusts when you modify the order

Queueing Print Jobs

Print Jobs Button: Click the "Print Jobs" button to:

- Open the standard print dialog for all jobs in the order

- Configure printer assignment (Next Available, Specific Printer, or Tagged Printers)

- Review material requirements across all jobs

- Add all jobs to the print queue simultaneously

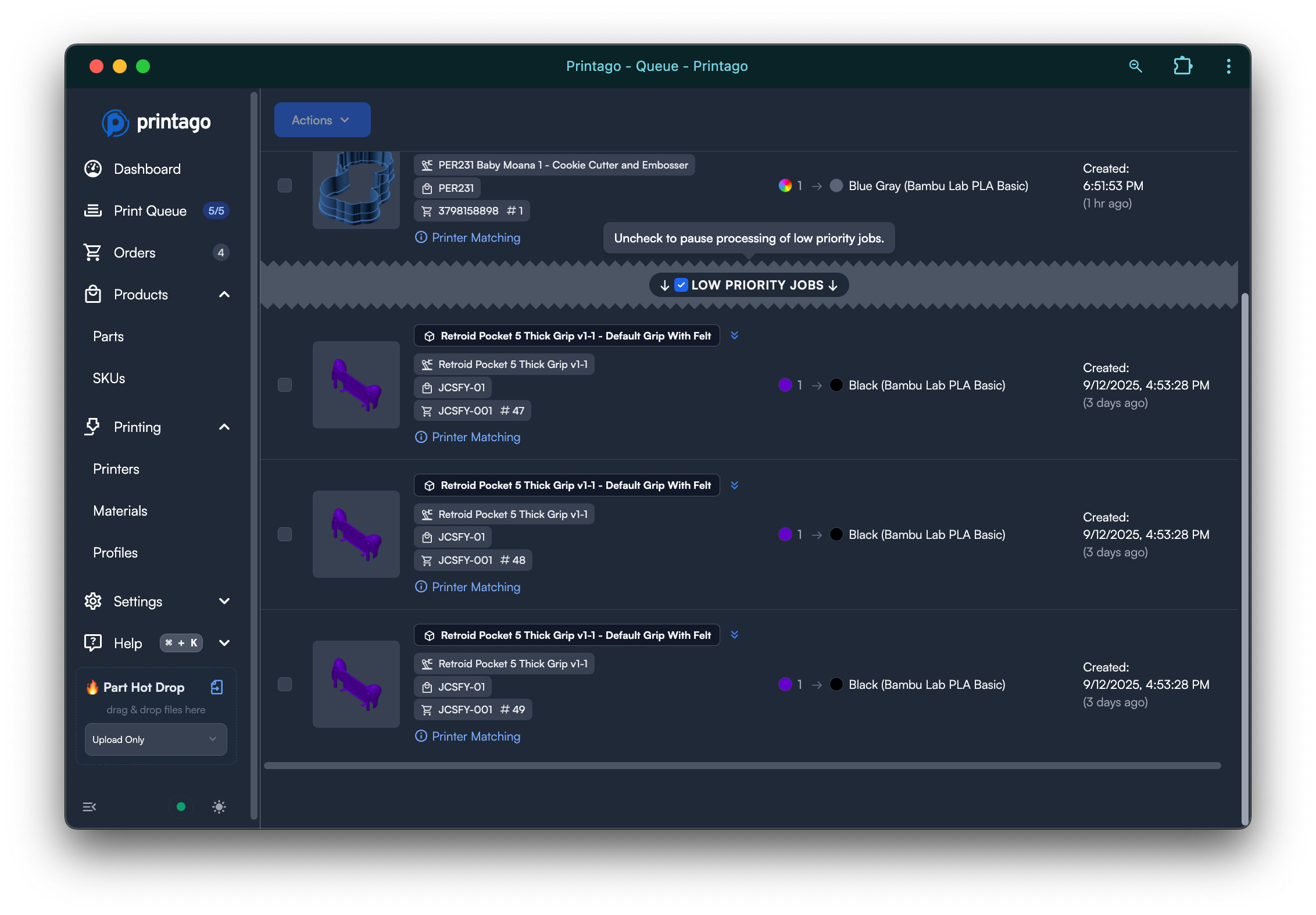

Queue Integration: Jobs from orders appear in the print queue with:

- Order number displayed for easy identification

- Clickable links back to the source order

- Ability to filter and sort by order number

Print queue showing jobs with order numbers (like JCSFY-001) and clickable order links

Order Management

Modifying Active Orders

Adding More Items:

- Add additional SKUs to existing orders

- Hit "Print Jobs" again to queue only the new items

- System automatically reconciles and adds new jobs without duplicating existing ones

Removing Items:

- Delete line items from orders

- Click "Print Jobs" to reconcile the queue

- Automatically removes cancelled line items from the print queue

- Doesn't affect jobs already in printing status

Order Status and Job Tracking

Job Status Awareness:

- Queued Jobs: Cancelling orders removes jobs from queue

- In-Progress Jobs: Cancelling orders leaves active prints undisturbed

- Completed Jobs: Order completion tracking based on job outcomes

Order Navigation:

- Click order numbers in the print queue to view full order details

- View all jobs associated with a specific order

- Track completion progress across all order line items

Closing Completed Orders

Order Completion Status:

- When all jobs for an order are completed, a green check appears next to the order in the orders list

- This visual indicator shows the order is ready to be closed

Closing Orders:

- Bulk Close: Check-select multiple completed orders and use the Actions menu to close them

- Individual Close: Click into a specific order and click the "Close" button

Order Tracking Features

Order Organization

Order History:

- All created orders remain accessible for reference

- Search and filter orders by customer, date, or order number

- Notes field maintains context and special instructions

Customer Management:

- Basic customer information (name and email)

- Order history per customer for repeat business

- Simple contact tracking for order follow-up

Production Planning

Fulfillment Dates:

- Set target completion dates for planning

- Visual indicators for order priority and timing

- Helps coordinate production scheduling across multiple orders

Material Planning:

- Preview material requirements before queueing jobs

- Aggregate material needs across entire orders

- Plan material loading for efficient production runs

Integration with Print Queue

Smart Assignment

Manual order jobs use all the same printer assignment features:

- Material Matching: Jobs only go to printers with correct materials

- Printer Tags: Route order jobs to specific printer groups

- FabMatic Support: Continuous printing works with order-based jobs

Order Tracking in Queue

Queue Visibility:

- Order numbers appear in job listings

- Click-through navigation from queue to order details

- Filter queue by specific orders for focused monitoring

Progress Monitoring:

- Track completion status of all jobs within an order

- Visual progress indicators for multi-SKU orders

- Completion notifications when entire orders finish

Common Use Cases

Custom Product Orders

- Customer requests multiple personalized items

- Configure OpenSCAD parameters for each line item

- Track entire order completion as a unit

Maker Space Projects

- Student or member requests for project components

- Organize all parts for a single project under one order

- Track material usage and completion for billing

Prototype Batches

- Engineering teams requesting test versions

- Multiple variations of the same design

- Coordinated completion for design review meetings

Event Production

- Conference giveaways or promotional items

- Multiple SKUs for complete event package

- Deadline-driven fulfillment date tracking

Need help with manual orders? Join our Discord community for support and tips from other users!