Print Queue

The Print Queue is where Printago's intelligent job management system, Gutenb3d, automatically matches your print jobs with the best available printers. Think of it as your print farm's mission control—routing jobs efficiently while you focus on what matters most.

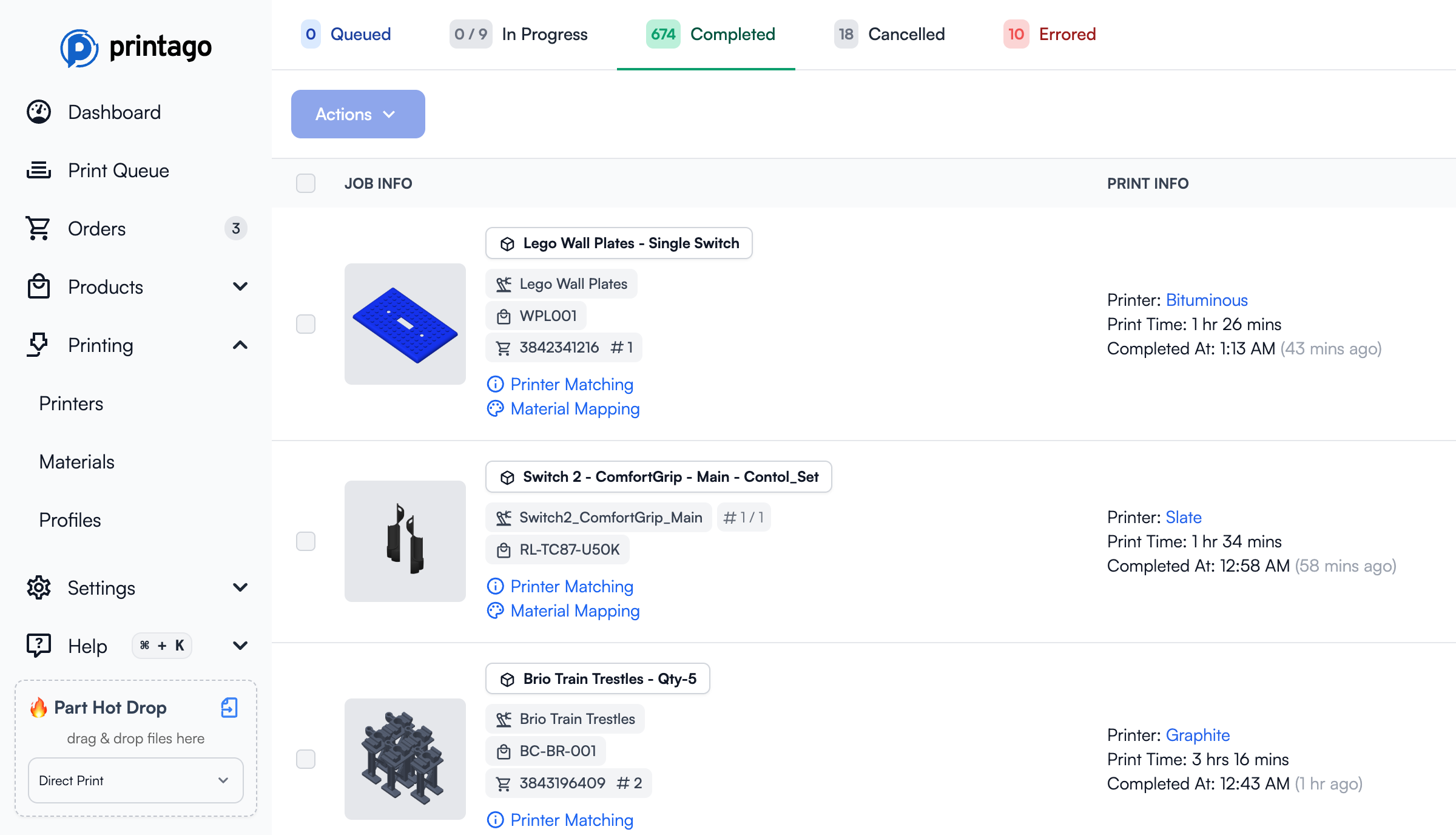

Understanding the Queue Interface

The Print Queue is organized into five tabs that represent different stages of your print jobs:

| Tab | Description | Available Actions |

|---|---|---|

| Queued | Waiting for printer assignment | Cancel, Move to Top, Drag/Drop reorder |

| In‑Progress | Actively printing on assigned printers | Pause, Resume, Cancel |

| Completed | Successfully completed prints | Retry, Clear |

| Cancelled | User-cancelled jobs | Retry, Clear |

| Errored | Jobs that failed during slicing or printing | Retry, Clear |

Job Interaction

Clicking the thumbnail of any job will show an interactive 3D model preview for STL and STEP files. This includes OpenSCAD or other Add-On output, allowing you to verify the generated output easily. You can also download the STL file from this window, which is particularly useful for OpenSCAD output.

After a job is sliced, this preview window will enable the Download GCODE button that was generated and sent to the printer.

Beyond thumbnail previews, you can also link directly to the SKU or Part associated with each job, and drag queued jobs to reorder their priority. All other job actions require selecting jobs with checkboxes and using the Bulk Action menus.

Why Jobs Wait in Queue

Every job starts in the Queued tab, even those sent "To A Specific Printer." Jobs remain queued when:

- No compatible printers are currently available

- All production slots are busy with other jobs

- Required materials or printer tags don't match any ready printers

In-Progress Jobs

Once Gutenb3d assigns a job to a printer, it moves to In-Progress and follows this path:

- Assignment - Job matched with compatible printer

- Material Mapping - Part materials mapped to printer's loaded filaments

- Slicing - Job automatically sliced for assigned printer

- Send & Print - Sliced file sent to printer, printing begins

After printing begins, in-progress job show their time remaining, percent complete and other statistics.

Print jobs started outside Printago (via slicer, Handy app, etc.) don't use production slots and won't appear here. You can monitor all printer activity on the Dashboard instead.

Job Outcomes

- Completed - Print finished successfully and reached end of gcode normally

- Cancelled - User stopped the job via Printago, slicer, Handy, or printer

- Errored - Job failed during slicing or printer halted due to issues (HMS errors, etc.)

Bambu Lab printer HMS events are reflected in the queue:

- HMS Warnings that pause printing (like filament runout) keep jobs in the In-Progress tab

- HMS Errors that halt printing move jobs to the Errored tab

When able, Printago provides a link to Bambu Lab's documentation on the HMS Code

How Smart Matching Works

Gutenb3d's intelligent matching system considers multiple factors when assigning jobs to printers:

Matching Criteria

| Criteria | Description |

|---|---|

| Printer Availability | Is the printer Available to Printago to assign any job? (see below) |

| Material Type | Specified on the part or SKU printed. May be things like "Any PLA" or "Bambu Basic PLA" |

| Material Variant | Material color, also stored on the part or SKU. |

| Printer Tags | Custom labels for organizing printer groups |

- Online and connected to Printago

- Not currently processing another job

- Marked as "clear & ready for next print"

Printer Assignment Strategy

Gutenb3d processes printers on a "last-used" basis to distribute wear evenly across your fleet. All your printers can receive jobs regardless of your commercial production slot limit—those slots only control how many jobs Printago actively manages simultaneously.

Managing Your Queue

Job Organization

- Each individual printed part appears as a separate queue item (even within multi-part SKUs)

- Use drag-and-drop to reorder job priorities within the same priority level

- Jobs process from top to bottom, with flexible reordering anytime

- Streamline management with Bulk Actions

Queue Priority

Printago supports two job priority levels:

- Normal Priority: Standard jobs that process first

- Low Priority: Jobs that only process when no normal priority jobs are available

Important Notes:

- Jobs cannot be dragged between priority groups (normal ↔ low)

- Use the multi-action dropdown to change priority for selected jobs

- Low priority jobs function identically to normal jobs, but only begin processing when the normal priority queue is empty

- Job priority can be adjusted at any time from the queue interface

Clearing completed jobs removes them from the interface but preserves all data for future reporting features. This soft-delete keeps the interface responsive while ensuring your print history remains available for upcoming analytics.

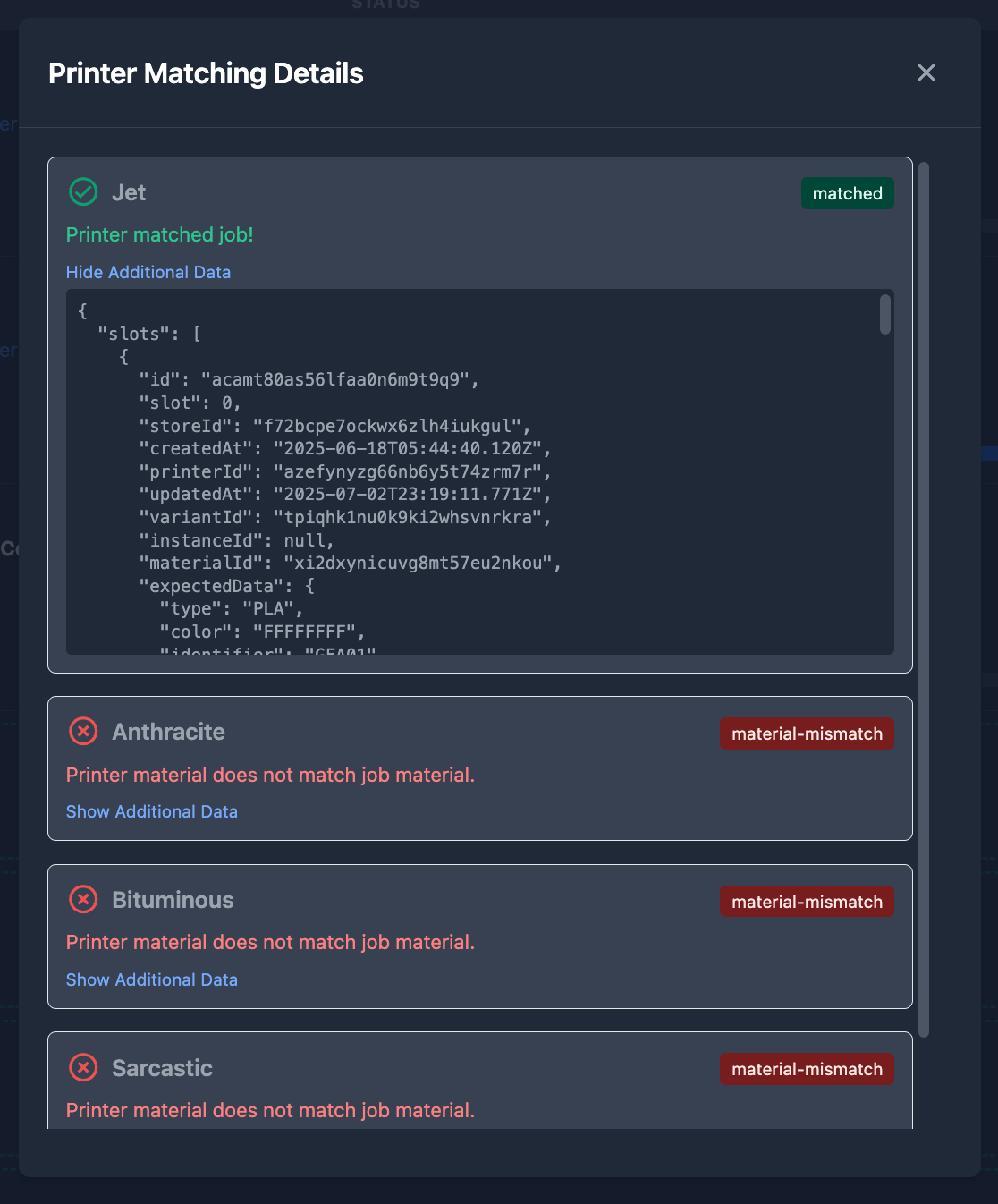

Troubleshooting Assignment Issues

Every job includes a Printer Matching dialog that shows:

- Which printers Gutenb3d attempted to match

- Specific reasons why each printer wasn't selected

Production Slot Management

Your production slots determine how many jobs Printago can actively manage at once. When slots are full:

- New jobs wait in the queue until slots become available

- Completed, cancelled, or errored jobs free up their slots immediately

- External prints (from slicers, apps, etc.) don't consume slots

This system ensures optimal resource allocation while maintaining full visibility of your entire print farm's activity.

Related Topics

- Bulk Actions - Efficient job management tools

- Cloud Slicer - Automatic slicing for assigned printers

Need help with your print queue? Join our Discord community for the latest tips and support!